Water hammer in water transfer pipelines.

Play PodcastJoined by Colin Kirkland, a mechanical engineer at Bermad, we dive into water hammer in water transfer pipelines. In this episode, we discuss the causes of, common locations where water hammer may take place, and what water hammer conditions look, feel and sound like, in a domestic appliance. Covering all the bases, Colin explains how the Bermad team work together to mitigate this condition and how the practical application and cost nature of the situation will determine which approach is adopted by the Bermad team.

Transcript

| Sarah | Hello and welcome to Controlling Water, a space for us to talk about water meters and interesting insights about the water industry. Each episode we’re joined in conversation by industry professionals that specialize in all things, valves, meters, and best practice knowledge in the water. We’re here with Colin Kirkland from Bermad Water Technologies, who is one of the engineers at BWT. Colin has over 30 years industry experience in working in pipelines that can be subject to water hammer.

Colin, I’m really excited to talk to you about this today. Water hammer is a topic and an area that we hear a lot about, and it’s also something where huge ramifications and consequences can occur if it’s not managed well, or if it’s not prevented or stopped. Before we get into some of the detail about water hammer, can you tell us what actually is water hammer? |

| Colin | Well, Water Hammer is a phenomenon that occurs where you see a very quick rapid increase in pressure way and above what you would normally expect in a pipeline generally caused by a rapid change of flow in the pipeline.

A really simple way of explaining this is the domestic household situation. In our house, I know what happens. When our clothes washing machine, when we start that, and the solenoid valve opens and the water runs into the clothes washer, when the water fills up to a level that solenoid turns off and you hear a bang and that’s because we’ve got a rapid change of flow happening cause the valve shuts off instantly pressure builds up and shakes the pipes. So that’s a small domestic situation of water hammer and can be changed. But the same thing happens in very large pipelines where there have been a mine or water supply to quite serious ramifications because it’s tons and tons of water potentially moving. |

| Sarah | No doubt. Wow.

And so when this water hammer condition happens in a pipeline, what are some of those ramifications? And is it dangerous as well? |

| Colin | Certainly it can be dangerous. Yes. Depending on the pipe material you’ve got, these pressure waves can run along the pipeline at very fast speeds. So in, in metallic pipe, for example, where it’s very, very rigid, it can run up to a thousand meters per second. So you might get a spike at a pump station and one second later, the kilometer of the air that pressure wave is transmitted through there. So it resonates through the whole network. The important thing is that when you see these pressure spikes, the network has to be able to cope with these now, like anything else, if you constantly fatigue a system by pressurizing it to a dangerous level, it can fail.

I’ve been in pump stations where I’ve sat at the pump station and they’ve turned the pumps off. And it’s quite scary when you hear the non return valve close and you hear this massive bang, everything shakes and this dangerous sort of thing. So, and we’ve had instances where if the products fail through fatigue and the excessive pressures, that can be dangerous to operators too, as well. So yes, it’s, it can be quite scary. |

| Sarah | Absolutely. Oh my goodness. So, what are the most common locations where water hammer happens in a water supply pipeline? Can we talk about that? |

| Colin | Typically it’ll happen in about three different locations, Sarah, so anywhere where the water flow changes rapidly, is where this is going to occur.

So if we think about a pumping station pumping to a reservoir, when the pump stops, that’s when the floor instantly changes. Now, if the pump slows down and ramps down very slowly, you don’t get the water hammer, but if it just stops instantly, that’s where we see it. Or you may see, for example, if you’re pumping to a reservoir, we may have a valve at the reservoir that says when I close, if I close too fast, I’m going to generate that water hammer, just like the washing machine effect. Or it could be that we’ve even got when a pipeline, a situation where the pipe is partially empty and you start the pump and that water columns come together. And when the two come together, the generate a rapid change in flow, and that can cause it there. I’ve even been on pipelines where I’ve heard operators running from the site because they’ve closed the valve too fast and they’ve heard air valves screaming. And that’s not a great situation. You know, these situations occur and people are not quite sure why they occur, but it can happen in multiple locations along the pipeline. |

| Sarah | That must be so scary to hear that on site and then have to run. |

| Colin | Well, it can be and that was an actual instance, which we had on a pipeline where we had a one meter diameter, butterfly valve close too quickly, and the air release valve next to it went into massive vacuum and the operators could hear this massive air being drawn in and ran from the site because they thought something was going to explode. And it wasn’t good. |

| Sarah | Not at all.

So having understood the areas that generate these water hammer issues. How does Bermad go about rectifying the solutions? |

| Colin | There’s two ways we look at it, Sarah. You can look to see what’s generating the problem, and you can try to rectify that. So, as an example of that, if the pump station was the situation that was generating the problem, because when they turned the pump off, it turned off in two seconds and they used to see our great amount of water hammer happenat the pump station.

So what could we do? We could extend the pump to make it run and shut over 30 seconds or 40 seconds and reduce that. Or what we could do is we could say, well, look, let’s just put a bandaid on it and put a pressure relief valve that if the pressure does rise, when we shut it off too quick, I can release. So it’s a case of one of two things: let’s look to see what the problem is and try and rectify that. Or let’s put a bandaid on to react to it |

| Sarah | Right. |

| Colin | The logic between going with one of the other, is the practical nature of it. It might be very expensive to put a solution in to stop the actual pump running down very slowly. We might have to put a pump control valve in there that might cost $20,000, or they might say, look, Colin, we’ve only got five years left in this on the mine. Let’s just put a relief valve in that can take out that spike. Keep it all. That might cost $3,000. So it’s the practical and the cost nature of what we’re looking at, but we look at it both ways. Try and fix the problem from happening or react to it. |

| Sarah | Definitely. And I guess it would always just depend on the situation at hand. |

| Colin | Completely, and the application too, Sarah.

So it might be that you’re doing this on an irrigation property where the irrigation grower, he’s spending his own money, and you know, the farm might want an inexpensive solution that’s not too cost worthy, but fixes it, or it might be a mine where you’re two kilometers underground. And when they turn that pump off, it’s seriously dangerous. The operators down there, they want the very best solution that’s going to fix it. So it could be that the water supply where we’ve got 40% of the water for a major city, we don’t want that to fail. So let’s put the most robust based system into maintain that. So it’s all horses for courses. |

| Sarah | Definitely. Definitely.

Let’s take a short break before we returned to chat about minimizing water hammer in complex installations with varying topography, You’re listening to Controlling Water, the Bermad podcast. Your primary source of insight for everything about water tech, valves, and meters. For more information on any of the products or topics discussed in this episode, plus a wide range of resources and articles designed to support you as water professionals, visit www.bermad.com.au. Now back to the show. So understanding these two general approaches to fixing the problem, where do you start to see what the best solution might be. |

| Colin | Yes. From our perspective, we’re not a consultant. We are an engineering company that produce solutions that we can put into pipelines. A company of course, can go to an independent consultant. And today, Sarah, there is many sizing modeling softwares that’s around such as Bentley, Hammer, K Y Pipe, High Trend, there’s many of them. But what these modeling softwares enable you to do is to accurately input the data of the pump, the pipe and the network, and actually see what happens if I stop the pump in 10 seconds or two seconds. Or if I have a power trip and the pump stops instantly, this is what will happen. And then they can identify and see how it’s going to affect the system and make suggestions. They may want to put a search tank in. They may want to put a pressure relief valve or an anti-semi release valve, or they may want to put a pump control valve in there’s many, many different ways you can look at it.

So from our perspective, we have almost 30 years experience in Australia in doing this. As, although we don’t do the modeling, we work with the modelers to show them how the valves are going to respond and do that. But we also have a lot of practical experience. So we commissioned a lot of our valves. We engineer them and make sure they work and we see them in action. So, modeling and actually experiences two completely separate things. And sometimes you will see a report from a model or that just doesn’t look right. And it’s usually because it’s kind of wrong input data and we have that experience to be able to share that so we can make the solution the best one. So from our perspective, we look at it from a experience. We know typically what works and if you want to back it up, you’ve got that software. You can go to companies together as well. |

| Sarah | It’s a really interesting point that you make around the ability to call out a potential error in modeling software through the years of experience. It also sounds like there’s a high value in being able to overcome blind spots, whether that’s through the software and being able to emulate situations or knowing actually that doesn’t look right and this is why. |

| Colin | And you’re very true there, Sarah, because what a lot of these programs assume is that the pipeline is completely filled full of water because water is non-compressible. But if there were pockets along the pipeline that had air in them that were compressible that can accentuate areas at different locations.

So it’s making a lot of assumptions. And look also, the software is not perfect, but it’s come an awful long way and what we see are coming from there and the reports is fantastic, you know, when it’s done well, but it’s not only just about having the software, but it’s actually having the engineer who really understands the software and knowing how to input the right data. And that takes a lot of experience. That’s why that’s left to specialists that do that, not me, but a lot of the time, the practical hands-on side of it also assist that and coming up with a good solution. Because the solution might not be practical. |

| Sarah | Very true. It’s really interesting that you mentioned air release valves. We’ve talked about that many times and we’ve certainly discussed the engineering benefits and some of the water hammer issues using air release valves. Do air valves on the pipeline prevent water hammer in the network? |

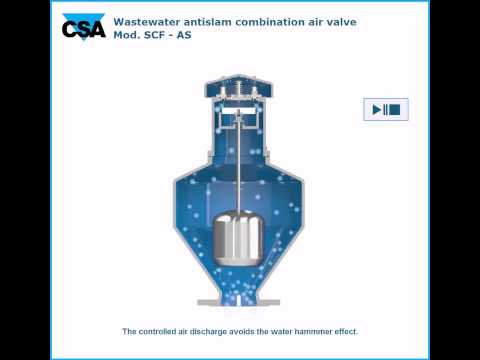

| Colin | Yes and no. So when you’re using that modeling software, typical air release valves, and we’re talking about a combination air valve, so that would mean if we had an 80 millimeter valve, it has an 80 millimeter orifice for air intake and the 80 millimeter orifice for discharge. Some air valves, if there’s column separation, and that’s where we have the pressure going into a negative or we’re drawing large amounts of air in, and then the columns come back together, they can generate localized water hammer at strategic locations. So they’re very good at protecting the pipe against vacuum. Very good at evacuating it, but with the wrong product and the wrong application, it can make it worse. And that’s where there are products in the market today, which are cold RFP, rapid filling prevention valves or anti-slam air release valves or surge prevention air valves, what these basically do is they say I’ll allow large amounts of air to come into the pipeline, but I will let the air out at a slower controlled rate. |

| Sarah | Right. |

| Colin | And there’s various ways that they actually achieved that function, but they’re very safe and they can be modelled very simply and easily on this software as well. |

| Sarah | How interesting. And so Colin, where should people start when they’re considering how to fix a water hammer issue? |

| Colin | Well, it depends on the application and it’s complexity. What we’re always trying to do, if they come to us at Bermad Water Technologies, we don’t provide this modeling software, but we provide 30 years of experience and getting it right. We can certainly give them advice on what’s generating the problem. And we tend to say when we come to sites sometimes, or we’ll discuss it on the phone or via zoom meeting or whatever. And we’ll be able to come up with what we believe is a solution. We’ll be able to give them some advice on how to install it, how it’s going to act, and also give them advice that if they actually want to model it and go to an independent company, we can show them how that works and they can prove it. So a lot of the times before you buy something you want to know, is it really going to work?

Well, we give a lot of references out for jobs that we’ve gotten and we’ve shared a lot of jobs that work well and don’t work as well and we’ve got the experiences. The big thing, Sarah, because you learn from mistakes a lot of the time and sometimes you make assumptions, which is incorrect. And that’s because we don’t see what’s actually underground. We don’t know if the pipe material was steel or if it was PVC. And that has an influence on how the valve reacts and speed, et cetera. So it’s quite a complex issue, but where do you start? We are a very good starting point to be able to start that conversation going for sure. |

| Sarah | Fantastic. Great to hear.

Colin, thank you for joining me today. It’s been a great conversation about water hammer. |

| Colin | That’s great. Thank you. |

| Sarah | For more learnings about the water industry, including products, tips, installations, operation, and maintenance techniques, head over to Bermad.com.au and subscribe to our industry newsletter. You’ll join more than 3000 industry professionals and learn from the experienced Burma team of industry specialists. Thanks for tuning into this episode of Controlling Water for more episodes, resources, and how to head to Bermad.com.au |

-

Colin has more than 40 years’ experience working in water supply and irrigation in Australia, including 24 years with BWT. He credits his training at Weir pumps in his native Scotland for providing him with a solid grounding in engineering.

Colin is a mechanical engineer and a fitter and turner, who prides himself on taking a hands-on approach when designing and implementing successful installations across all aspects of BWT’s products and markets.

Read more about Colin: Who’s who at BWT – Colin Kirkland

Want more details?

To get more information about the training topics we offer, get in contact with our experts.

Online Enquiry Close

Products

Videos

How To's

Read more

Read more

How Tos

How To Stop Water Hammer in Your Pipe Network

Read more

Read more

How Tos

Water Hammer Solution in Multistorey Building Applications

Read more

Read more

How Tos

How To Minimise Water Hammer in Pumping Stations Using Anti-Slam Air Valves

Read more

Read more

How Tos