This course covers the fundamentals when it comes to understanding and operating hydraulic control valves.

Here, you’ll find information on the design of single and double chamber valves, how they operate, and how to use them across a variety of applications.

Other information covered in this course includes:

– Inner actuator design

– Single and double cavitation

– Orifice plates

– V port throttling plugs

– Valve longevity

– Sizing design software

The control valve principles and valve selection course ensures your valve selection, installation and maintenance is done correctly and fit for every application.

Ideal for designers, operators and maintenance staff, this course will cover how control valves operate, fail in operation, as well as maintenance and prevention when it comes to failure.

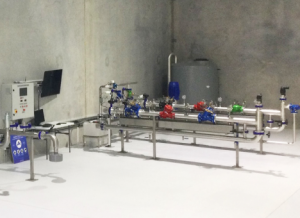

In this hands on course, you’ll work with the valves on our testing rig. You’ll learn best-practices for installation, ease of operation, and the accessories required to achieve effective installation and maintenance.

In this course, we’ll discuss the issues that may arise in pump stations that reflect water hammer in pipeline systems.

Here, we’ll demonstrate the different techniques used to avoid pump cavitation, and the methods that minimise the effects of water hammer in water networks.

This course covers single and multiple pump stations, booster pump stations, and a wide variety of pump station designs.

Learn about the hydraulic requirements needed to design an effective pressure reducing station for water supply, the specific designs needed for redundancy and maintenance, and what a well designed pressure reducing valve station looks like.

Incorporating associated components such as: strainers, isolation valves, pressure relief valves, air valves and plumbing fittings, we’ll cover everything needed to combine for a practical station.

In this course, we’ll discuss what an electronic control valve is, how SCADA is used in a variety of applications, such as: water transfer, altitude filling and basin filling.

We’ll discuss how to control valves via PLC control, how to link to telemetry, for both local or remote operation, and the different aspects of station design and maintenance.

This course will cover the different designs and functions performed by a control valve when filling tanks, basins or reservoirs.

Topics covered in this course:

– Best-practice designs

– Interaction with pump stations

– Interaction with gravity pipelines

– Valve selection

– Noise considerations

– Water quality issues

– Valve cavitation

– Water supply network designs

Here, you’ll learn about the complex condition of valve cavitation caused by burning high differential pressures across a variety of control valve applications.

This course will demonstrate how anti-cavitation valve design can be achieved safely without impacting on excessive valve wear and deterioration. In addition to this, we’ll discuss how to minimise noise at higher differentials and ensure practical designs are achieved in a multitude of external environments.

Learn about the different requirements needed when designing a pipeline that incorporates air release valves.

Covering off designs fit for raw water or drinkable water pipelines, we’ll discuss and determine the functions, operations, connections, and techniques involved to create a successful design.

This course will help you determine the effectiveness of the different valve sizes across a range of individual pipe applications. Highlighting best-practice design installations and demonstrations, this course will ensure your air valve can operate effectively, efficiently, and without water hammer.

This course covers the requirements needed when designing a pipeline with air release valves for raw sewage or slurry pipelines.

Here, we’ll discuss the different designs for various air release valves, their functions, operations, and connections to the different pipeline techniques.

We’ll cover how to correctly effectively size and select valves across individual applications, as well as best-practice design installations and odour control techniques to ensure that your valves are working effectively in pipelines without water hammer.

This course provides insight into how electromagnetic meters operate and their purpose in water supply and sewage systems.

We’ll discuss various installation techniques, communication options, and the methods of powering different designs.

We’ll showcase best-practices for engineering, demonstrate the different installation techniques used to ensure accurate and effective operation, and how to integrate them into telemetry.

This course will cover the different technologies applied in mechanical water meters that are used for billing purposes in water supply.

Here, we’ll discuss the wear and tear, accuracy and best-practice engineering techniques used across domestic water supply.

We’ll showcase, and demonstrate, how to read meters remotely using various designs of communication from the meter to remote reading devices, as well as the requirements for water companies in relation to the standards that ensure the meter is used correctly for long-term installation.

Most water companies have specific requirements when it comes to the installation of suitable electromagnetic flow meters.

This course considers the varying requirements needed when it comes to reading trade waste discharge meters and discusses the different design methods, and the variety of communication forms; from the meters, to remote readers, to ensure effective installation occurs.

Do you have a specific requirement for training on any of the Bermad Water Technology products or services?

Speak to our team to get more information about the training topics we offer. Get in touch with our experts and submit an enquiry form.