Air pockets in Magflow meters: A hidden accuracy threat

![Euromag Euromag flow meter]()

Entrapped air in a pipeline can cause several issues with the accuracy of your Magflow meter. This article discusses the issue of over-reading, which can occur without warning unless the meter has the capability to detect it.

Meters used in urban and non-urban applications require different pattern approval certificates. While all certificates require the meter to perform within a specific accuracy, outside of a controlled laboratory setting, Magflow meters can have large errors that can go undetected.

The Magflow’s principle of operation

All Magflow meters generate a magnetic field inside the flow tube (sensor). The movement of water through the pipe generates a potential difference that is directly in proportion to the flow rate. The readings are highly accurate and have the benefit of no moving parts.

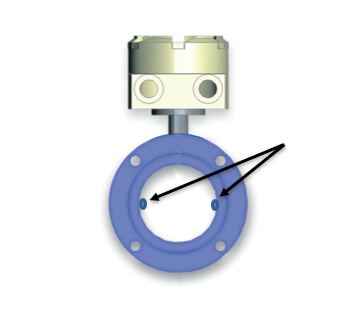

The electrodes that measure the induced voltage signal are located in the middle of the flow tube.

The arrows refer to the sensing electrodes on the meter.

The meter’s signal is generated based on the flow rate, which is used in the calculation of the volume of water that has passed through the meter. This calculation is only accurate if the meter is completely full.

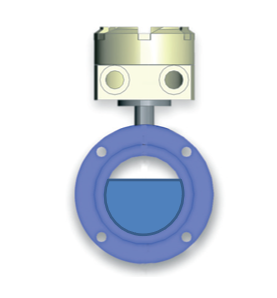

The illustration below shows a pipe that has a large air pocket. In this example, the pipe is only 75% full. However, due to the entrapped air, the sensing electrodes will measure the same signal as if the pipe is completely full. Due to this inaccurate read, the calculated volume of the meter will be 25% more than has actually passed through the meter.

The percentage of air that is inside the flow tube is also the percentage that the meter will over-read. This can result in the customer being over-billed without any knowledge.

A meter with entrapped air and 75% full.

Detecting air in a Magflow

Many Magflow meters will state that they have empty pipe detection. This monitoring is completed by the sensing electrodes. In the case of entrapped air, these meters will only detect an empty pipe when the meter is half empty. The example above would remain undetected.

The best method of detecting air in a Magflow meter is to have a dedicated empty pipe electrode. To ensure the electrode always detects air, the electrode should be located at the highest point inside the flow tube.

Empty pipe electrode.

When the meter has a dedicated empty pipe detection, as shown above, the meter will raise an empty pipe alarm on the display as a warning.

Some Magflow meters have an electrode at this highest point inside the flow tube, though commonly they are used for grounding and not empty pipe detection. To avoid the possibility of over-reading make sure the Magflow has a dedicated empty pipe electrode.

Assistance with avoiding entrapped air in your system

Our Knowledge Hub has a variety of articles to help support the optimisation of your system. One of our latest articles best explains some of the considerations that should be made to avoid entrapped air.

Alongside this article, we have a range of technical data that may assist you with your metering network, as well as video demonstrations to support your product knowledge.

If you’d like dedicated assistance with your pipeline or meter, you can also get in touch with us directly online, or by contacting your local sales office.

Make enquiry

Online Enquiry Close

Entrapped air in a pipeline can cause several issues with the accuracy of your Magflow meter. This article discusses the issue of over-reading, which can occur without warning unless the meter has the capability to detect it.

Meters used in urban and non-urban applications require different pattern approval certificates. While all certificates require the meter to perform within a specific accuracy, outside of a controlled laboratory setting, Magflow meters can have large errors that can go undetected.

The Magflow’s principle of operation

All Magflow meters generate a magnetic field inside the flow tube (sensor). The movement of water through the pipe generates a potential difference that is directly in proportion to the flow rate. The readings are highly accurate and have the benefit of no moving parts.

The electrodes that measure the induced voltage signal are located in the middle of the flow tube.

The arrows refer to the sensing electrodes on the meter.

The meter’s signal is generated based on the flow rate, which is used in the calculation of the volume of water that has passed through the meter. This calculation is only accurate if the meter is completely full.

The illustration below shows a pipe that has a large air pocket. In this example, the pipe is only 75% full. However, due to the entrapped air, the sensing electrodes will measure the same signal as if the pipe is completely full. Due to this inaccurate read, the calculated volume of the meter will be 25% more than has actually passed through the meter.

The percentage of air that is inside the flow tube is also the percentage that the meter will over-read. This can result in the customer being over-billed without any knowledge.

A meter with entrapped air and 75% full.

Detecting air in a Magflow

Many Magflow meters will state that they have empty pipe detection. This monitoring is completed by the sensing electrodes. In the case of entrapped air, these meters will only detect an empty pipe when the meter is half empty. The example above would remain undetected.

The best method of detecting air in a Magflow meter is to have a dedicated empty pipe electrode. To ensure the electrode always detects air, the electrode should be located at the highest point inside the flow tube.

Empty pipe electrode.

When the meter has a dedicated empty pipe detection, as shown above, the meter will raise an empty pipe alarm on the display as a warning.

Some Magflow meters have an electrode at this highest point inside the flow tube, though commonly they are used for grounding and not empty pipe detection. To avoid the possibility of over-reading make sure the Magflow has a dedicated empty pipe electrode.

Assistance with avoiding entrapped air in your system

Our Knowledge Hub has a variety of articles to help support the optimisation of your system. One of our latest articles best explains some of the considerations that should be made to avoid entrapped air.

Alongside this article, we have a range of technical data that may assist you with your metering network, as well as video demonstrations to support your product knowledge.

If you’d like dedicated assistance with your pipeline or meter, you can also get in touch with us directly online, or by contacting your local sales office.

Make enquiry