Altitude valve for elevated tanks

![Article_Header_AltitudeValve]()

This piece provides a detailed overview of altitude valves, including the two main types, common applications, key features and components of the valves’ design, and more.

What is the function of an altitude valve?

An altitude valve is a pilot-operated valve that opens and closes to fill a high-level tower or tank hydraulically. The valve performs this function by sensing the static level of water in the tower.

The control valve has a high-sensitivity three-way positioning pilot that diverts water to the control chamber once the top level is reached, thereby making the valve close.

When water is at a low level in the tower, the pilot senses the need to open. In these instances, water is vented from the chamber, making the valve open to re-fill the tank.

The difference between opening and closing of the tank is pre-set in the pilot to approximately one metre. However, if greater differentials are required, a send pilot is fitted to create an adjustable differential between opening and closing.

As the flows filling the tank are typically quite high, both the opening and closing speed is carefully controlled to ensure there is no risk or impact caused by water hammer during the function of the valve.

What is the difference between an altitude valve and a modulating altitude valve?

A modulating altitude valve is similar in design to the regular altitude valve, except it incorporates a high sensitivity 2-way altitude pilot instead of the three-way pilot.

Rather than purely opening and closing—like the three-way pilot used in an altitude valve—the pilot modulates the main valve to maintain a constant level in the tank.

When the water is at the top level for the tank, the valve closes at a slow, controlled rate. As the level drops slightly, moving away from the top closing level, the valve starts to open slightly. This ‘tops up’ the water level. If the level continues to drop, the valve opens further to regain any loss of water level.

Conversely, as the level rises, the valve slows the flow down gradually. It will eventually close fully when the top water level is reached.

How is an altitude valve used? What are some of the common applications?

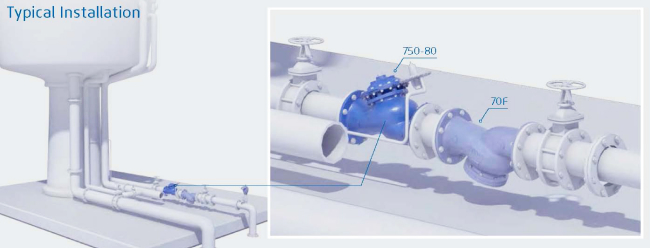

- The valve is typically located at ground level on the horizontal or vertical leg, flowing upward to fill the high-level tower. As there is no float in the tank, the pilot operates by sensing a static level in the tower. This ensures accurate readings.

- The valve usually only operates flow in one direction. When configured as a double chamber valve, it can also provide a non-return function.

- Some applications require bi-directional flow for filling and draining. This can be configured in a slightly modified design, if needed.

- Often, when the altitude valve opens and fills the reservoirs, the valve may be required to keep the inlet pressure to a minimum requirement, to supply users prior to the tank. A pressure sustaining valve can also be added to the altitude function if required, to enable the valve to modulate the incoming pressure.

- In other supply networks when the valve opens, it may be required to limit the flow to ensure than biofilms are not stripped from the incoming pipework under higher velocities. If unresolved, this can lead to water quality issues in the tank, which should be avoided at all costs. A function to control the flow can be added using one of two approaches: fitting a mechanical flow stem or a hydraulic send pilot to limit the flow.

What are the main components of an altitude valve?

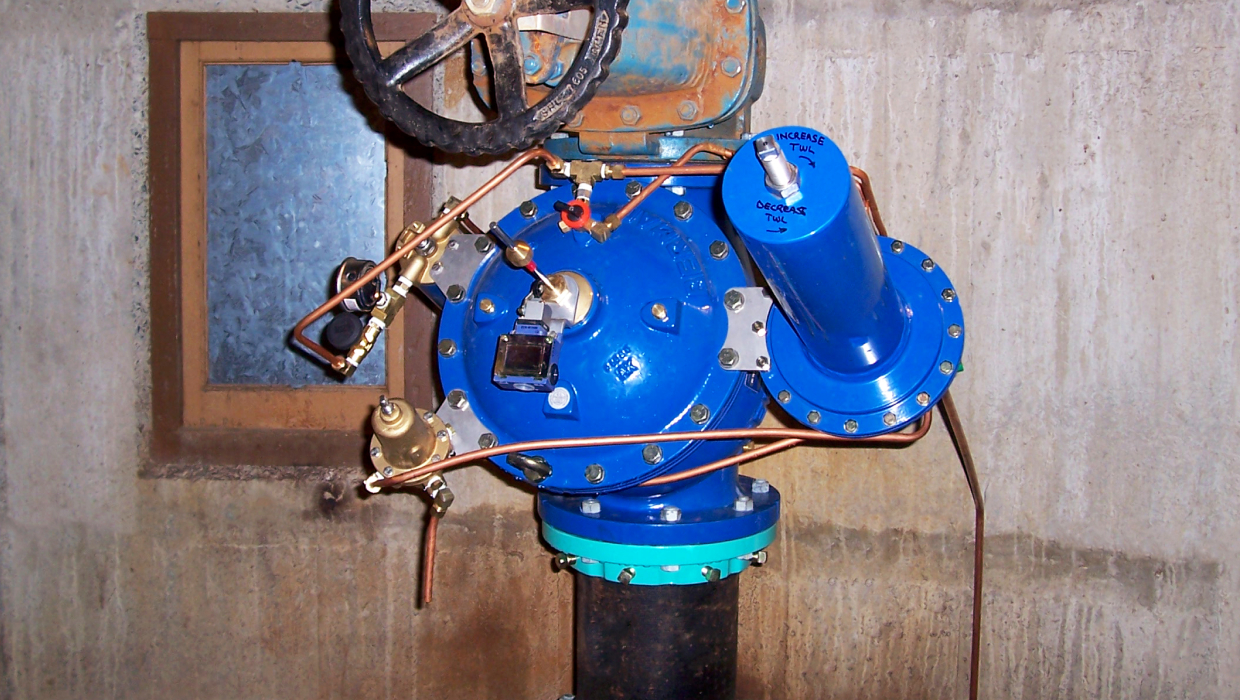

When it comes to choosing an altitude valve, the Bermad 750-80 altitude valve incorporates many key design features and functionalities that make it an ideal solution. These include:

- Valve body: The Y-pattern double chamber 700 series valve body is designed to operate with exceptional accuracy and levels of performance. The forces inside the valve cause it to open and close positively without surges. Watch the following animations for more detail on the principles and performance of the double chamber valve:

- Pilot regulator: The Bermad three-way pilot regulator is the ‘brain’ of the valve. It will trigger the valve to open and close as necessary by sensing the level of water in the tower. Learn more about pilot regulators.

- Large control filter: In order for the valve to perform at the highest level with minimum requirement for maintenance, it is critical to filter any water entering the pilot. The Bermad Large Control Disc Filter is an oversized filter with a series of fully cleanable disc elements. It protects the pilot from any organic and inorganic particles that are greater than 200 microns. The oversized design of the filter reduces the frequency of required maintenance, and reduces the risk of valve malfunction in the off chance the filter becomes blocked by dirty water.

How to set an altitude valve for operation

Created for operators, this video highlights the step-by-step methods required to set the control valve:

Learn more about altitude valves

If you’re using or considering a Bermad altitude valve, we’re proud to provide everything you need for high performance in the field. Helpful resources include:

- A detailed overview of the Bermad 750-80 altitude valve, with data sheets, instruction manuals, CAD drawings, REVIT files, and more.

- The opportunity to participate in hands-on, practical training sessions with experienced product specialists at your local Bermad Interactive Training Facility.

- Contact your nearest sales office to discuss altitude valves and your unique application requirements with experienced technical specialists.

- Use our live field support platform for assistance and advice in the operation of any valve.

Make enquiry

Online Enquiry Close

This piece provides a detailed overview of altitude valves, including the two main types, common applications, key features and components of the valves’ design, and more.

What is the function of an altitude valve?

An altitude valve is a pilot-operated valve that opens and closes to fill a high-level tower or tank hydraulically. The valve performs this function by sensing the static level of water in the tower.

The control valve has a high-sensitivity three-way positioning pilot that diverts water to the control chamber once the top level is reached, thereby making the valve close.

When water is at a low level in the tower, the pilot senses the need to open. In these instances, water is vented from the chamber, making the valve open to re-fill the tank.

The difference between opening and closing of the tank is pre-set in the pilot to approximately one metre. However, if greater differentials are required, a send pilot is fitted to create an adjustable differential between opening and closing.

As the flows filling the tank are typically quite high, both the opening and closing speed is carefully controlled to ensure there is no risk or impact caused by water hammer during the function of the valve.

What is the difference between an altitude valve and a modulating altitude valve?

A modulating altitude valve is similar in design to the regular altitude valve, except it incorporates a high sensitivity 2-way altitude pilot instead of the three-way pilot.

Rather than purely opening and closing—like the three-way pilot used in an altitude valve—the pilot modulates the main valve to maintain a constant level in the tank.

When the water is at the top level for the tank, the valve closes at a slow, controlled rate. As the level drops slightly, moving away from the top closing level, the valve starts to open slightly. This ‘tops up’ the water level. If the level continues to drop, the valve opens further to regain any loss of water level.

Conversely, as the level rises, the valve slows the flow down gradually. It will eventually close fully when the top water level is reached.

How is an altitude valve used? What are some of the common applications?

- The valve is typically located at ground level on the horizontal or vertical leg, flowing upward to fill the high-level tower. As there is no float in the tank, the pilot operates by sensing a static level in the tower. This ensures accurate readings.

- The valve usually only operates flow in one direction. When configured as a double chamber valve, it can also provide a non-return function.

- Some applications require bi-directional flow for filling and draining. This can be configured in a slightly modified design, if needed.

- Often, when the altitude valve opens and fills the reservoirs, the valve may be required to keep the inlet pressure to a minimum requirement, to supply users prior to the tank. A pressure sustaining valve can also be added to the altitude function if required, to enable the valve to modulate the incoming pressure.

- In other supply networks when the valve opens, it may be required to limit the flow to ensure than biofilms are not stripped from the incoming pipework under higher velocities. If unresolved, this can lead to water quality issues in the tank, which should be avoided at all costs. A function to control the flow can be added using one of two approaches: fitting a mechanical flow stem or a hydraulic send pilot to limit the flow.

What are the main components of an altitude valve?

When it comes to choosing an altitude valve, the Bermad 750-80 altitude valve incorporates many key design features and functionalities that make it an ideal solution. These include:

- Valve body: The Y-pattern double chamber 700 series valve body is designed to operate with exceptional accuracy and levels of performance. The forces inside the valve cause it to open and close positively without surges. Watch the following animations for more detail on the principles and performance of the double chamber valve:

- Pilot regulator: The Bermad three-way pilot regulator is the ‘brain’ of the valve. It will trigger the valve to open and close as necessary by sensing the level of water in the tower. Learn more about pilot regulators.

- Large control filter: In order for the valve to perform at the highest level with minimum requirement for maintenance, it is critical to filter any water entering the pilot. The Bermad Large Control Disc Filter is an oversized filter with a series of fully cleanable disc elements. It protects the pilot from any organic and inorganic particles that are greater than 200 microns. The oversized design of the filter reduces the frequency of required maintenance, and reduces the risk of valve malfunction in the off chance the filter becomes blocked by dirty water.

How to set an altitude valve for operation

Created for operators, this video highlights the step-by-step methods required to set the control valve:

Learn more about altitude valves

If you’re using or considering a Bermad altitude valve, we’re proud to provide everything you need for high performance in the field. Helpful resources include:

- A detailed overview of the Bermad 750-80 altitude valve, with data sheets, instruction manuals, CAD drawings, REVIT files, and more.

- The opportunity to participate in hands-on, practical training sessions with experienced product specialists at your local Bermad Interactive Training Facility.

- Contact your nearest sales office to discuss altitude valves and your unique application requirements with experienced technical specialists.

- Use our live field support platform for assistance and advice in the operation of any valve.